Of course, you can also reach us via e-mail or our contact form. We will get in touch with you as soon as possible.

Not everything you need to manufacture your own product you actually produce yourself. Instead, products from suppliers are used. The challenge here is that your own quality depends to a large extent on the quality of the supplier products and the reliability of the suppliers. So, which is the best? The lower the vertical integration of a company, the more dependent it is on suppliers.

Read here how you can use supplier assessment to find the right supplier and strengthen partnership-based collaboration:

Supplier assessment is a subarea of supplier management that enables the objective evaluation and comparability of suppliers. The aim is to use this comparability to either select a suitable supplier or to increase supplier quality through ongoing evaluation.

By selecting and developing suitable suppliers through efficient supplier evaluation, companies achieve optimization of the supplier process, strengthen the partnership relationship with their suppliers and ultimately increase their own corporate success.

Supplier assessment is a core task of the purchasing department, which is responsible for the acquisition of supplier products – and thus also for the selection of suitable suppliers. But how does the purchasing department go about it? Research based on audits, customer evaluations, tours of production facilities, certificates and sample deliveries alone is not enough. Rather, an evaluation system suitable for the company must also be developed and introduced.

One such method would be the point evaluation process, in which suppliers receive points or grades for selected criteria. These scores are awarded by people who are in direct contact with the supplier. This method is easy to use but can also be subjective. An alternative is the profile analysis, which enables a direct comparison between two or more suppliers. Here, the strengths and weaknesses of the suppliers in the individual categories are placed in relation to the requirements of the company. Accordingly, this method is particularly suitable for comparing different suppliers with each other when selecting a supplier.

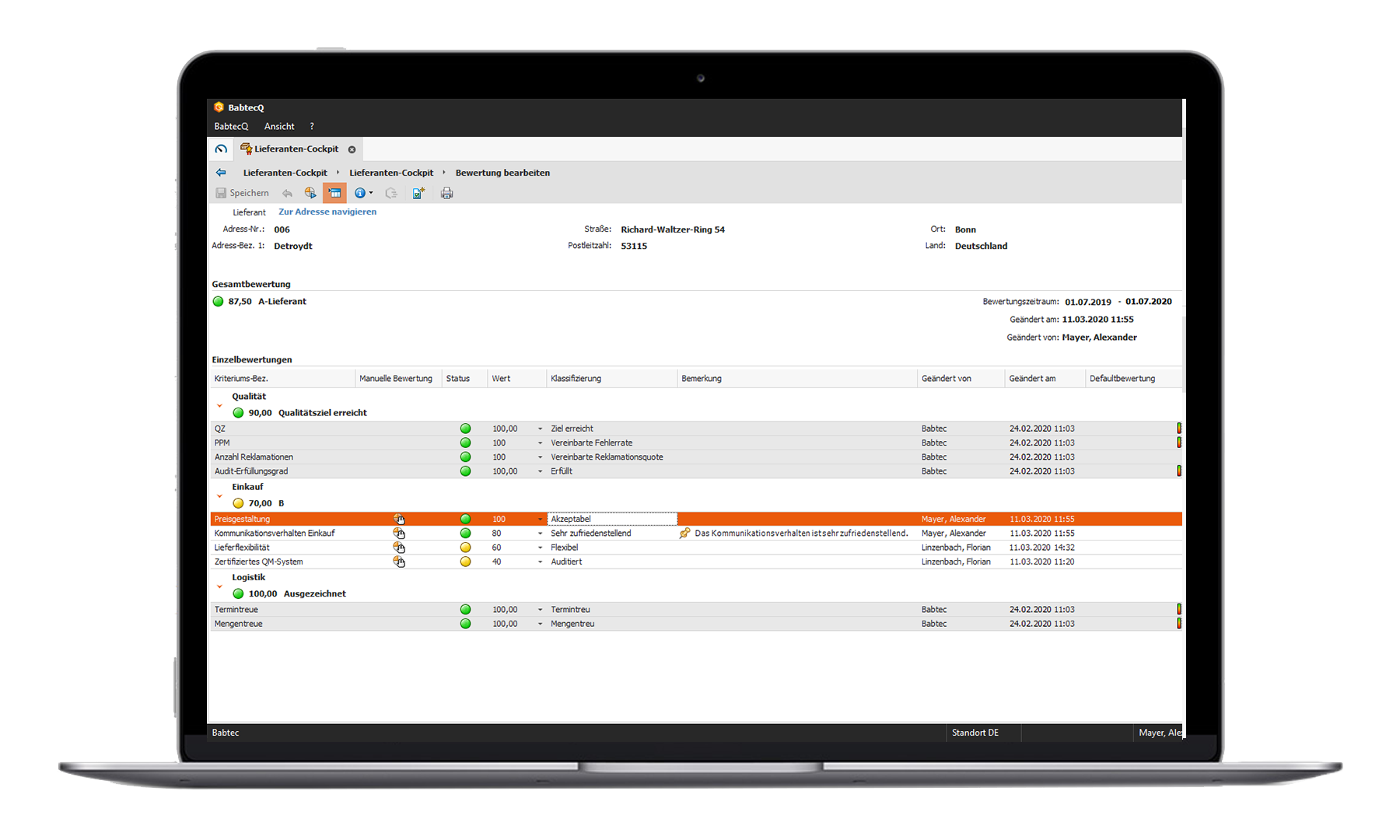

The criteria that should be considered in supplier evaluation are not prescribed by any standard, but they are often similar. Depending on the company and the priorities set, an individual set of criteria can be defined. The classification of suppliers on the basis of these criteria is often carried out within the framework of the ABC categories (A corresponds to the preferred suppliers, B to those that should still be developed and C to those that will not be commissioned).

The following criteria could be part of a supplier assessment, for example:

The purchasing department must ensure the quality of the purchased products. The greater the influence of the supplier product on the quality of the end product, the more important the supplier evaluation. In addition, this is required by DIN EN ISO 9001:2015: if supplied products are integrated into the company’s own product, companies must evaluate their suppliers on the basis of criteria of their own choosing and document the results. The timing for this is not prescribed. Accordingly, companies are free to decide how regularly supplier assessments are to be carried out.

The end-to-end evaluation and classification of suppliers has many advantages: it can help to identify risks at an early stage, develop relationships in a targeted manner, and avoid costs arising from inadequate performance. In addition, timely and transparent communication significantly strengthens cooperation based on trust. Regular supplier assessments are also advisable with regard to the legal situation (keyword supply chain law). Ultimately, every company benefits from a partnership-based relationship with its suppliers in competition. The same also applies to the suppliers: they receive feedback on their strengths and weaknesses and are shown potential for further development.

Companies that have to manage and assess many suppliers quickly reach their limits without supporting tools. For them, software that manages supplier and product documentation as well as supplier assessment in a simple and structured manner is indispensable.

Knowing and systematically expanding the qualifications of one’s own employees is not only necessary, but also very sensible. This is the only way to ensure sustainable quality in the company and the satisfaction of the workforce. A helpful tool for this is the qualification matrix. You can read here... continue reading

Anyone involved in quality management and QM systems has probably already come across the term skip lot procedure. This article explains what this sampling procedure is all about and why it can be useful. The term skip-lot (skip a lot) actually brings us pretty close to the general idea: Because this... continue reading

All over the world, automotive manufacturers install supplier parts in a wide variety of vehicle models. Those who collect, standardize and analyze field data as part of their warranty management know the failure behavior of their own products – and can initiate suitable corrective measures at an early... continue reading

No Comments