Of course, you can also reach us via e-mail or our contact form. We will get in touch with you as soon as possible.

An FMEA follows the principle of identifying potential failures as early as during the product development process by analyzing and assessing possible risks. Then, by planning appropriate actions early, causes of failure can be effectively avoided. In addition to this risk analysis, you bundle valuable knowledge about products and processes in Failure Mode and Effects Analyses already from the development stage. Once this knowledge has been included, you can refer to it again in each new FMEA. The software solution from Babtec makes it easier for you to plan, execute and document your FMEA.

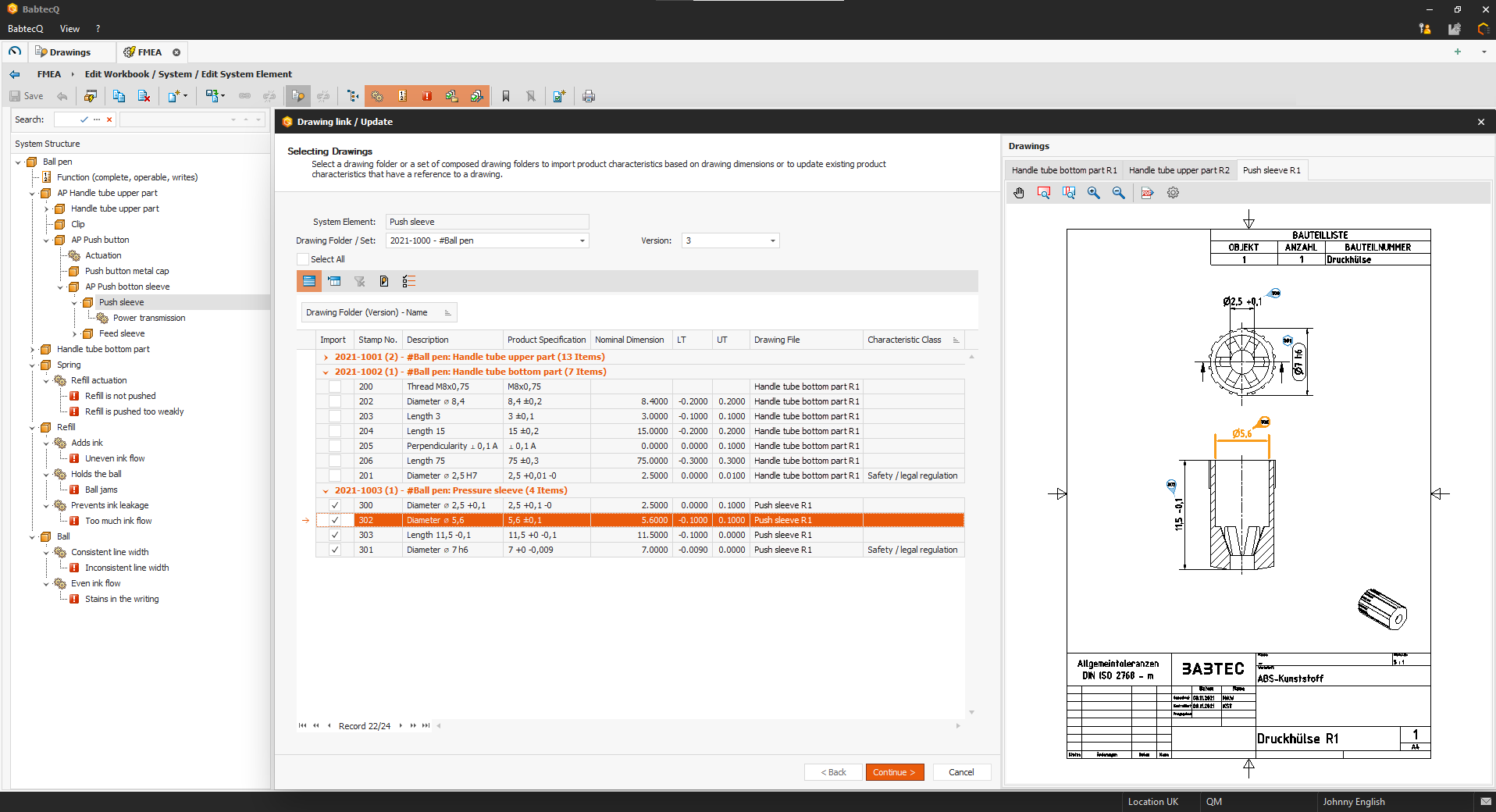

As a module of the integrated QM software BabtecQ, the software solution for FMEA supports you in planning, executing and documenting standards-compliant design and process FMEAs. The goal of the design FMEA is to detect possible weak points in the product design and to reduce their risks even before the new product is released for production. For a new product, the process FMEA particularly considers all value-added process steps of the planned production, assembly and logistics processes.

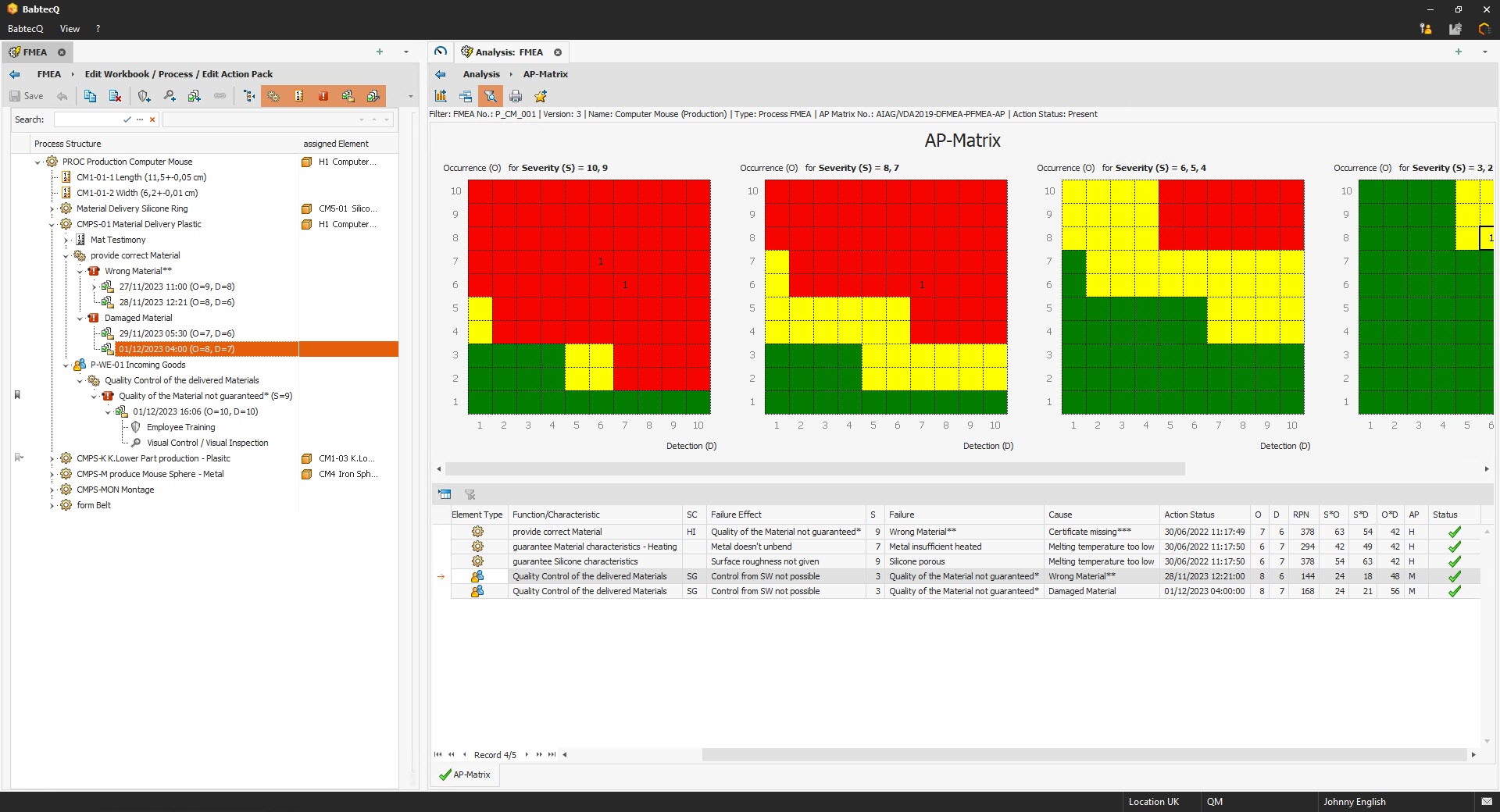

Through these analyses, our FMEA program provides a risk assessment of the identified possible faults. Primarily, however, it provides appropriate actions that, when implemented, can effectively minimize the identified risks in the development and manufacture of the product. Within the software for FMEA, you apply the systematic and structured 7-step procedure. This is recommended by the two major automobile associations AIAG and VDA and has also become established in other industries.

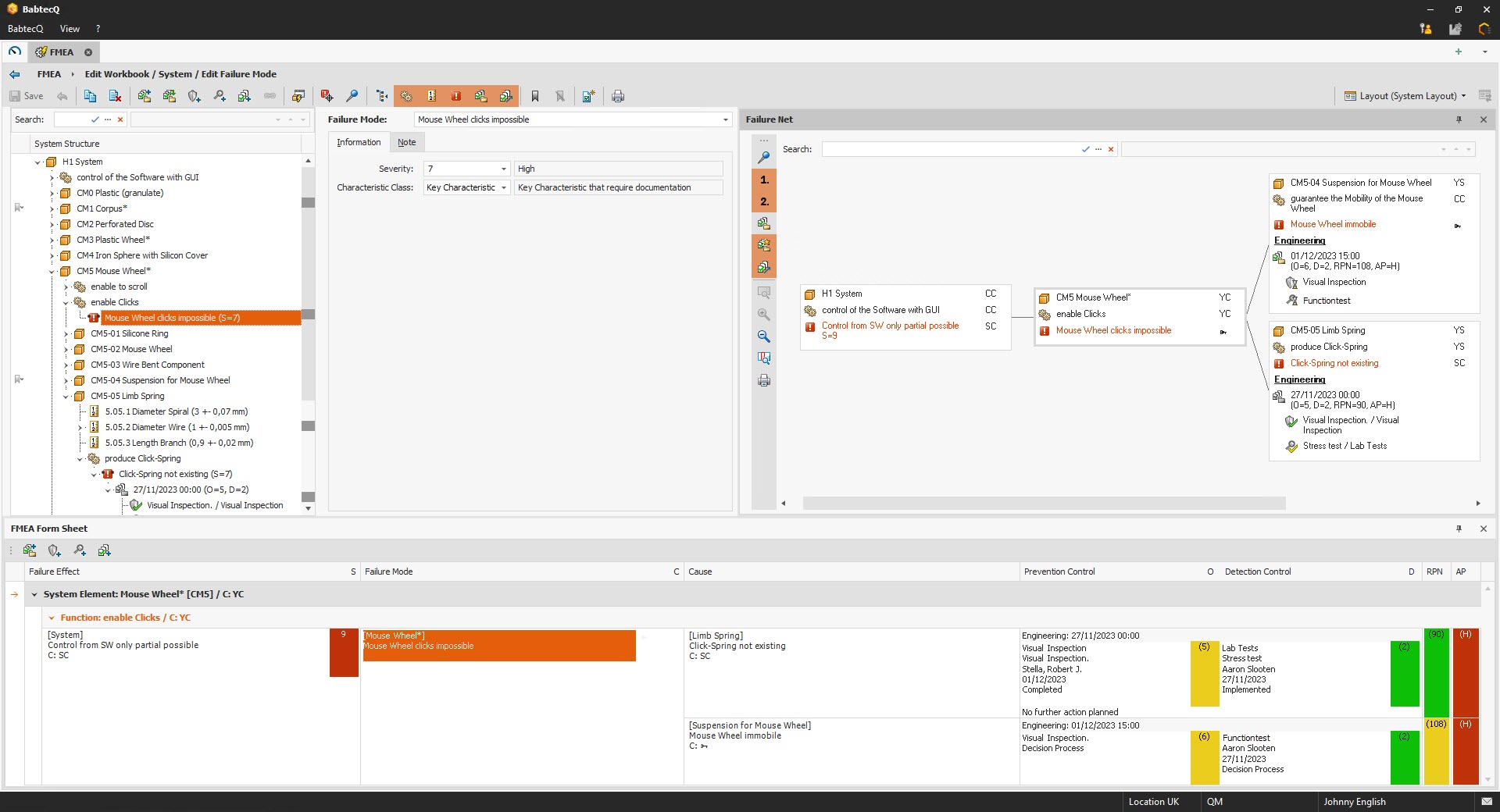

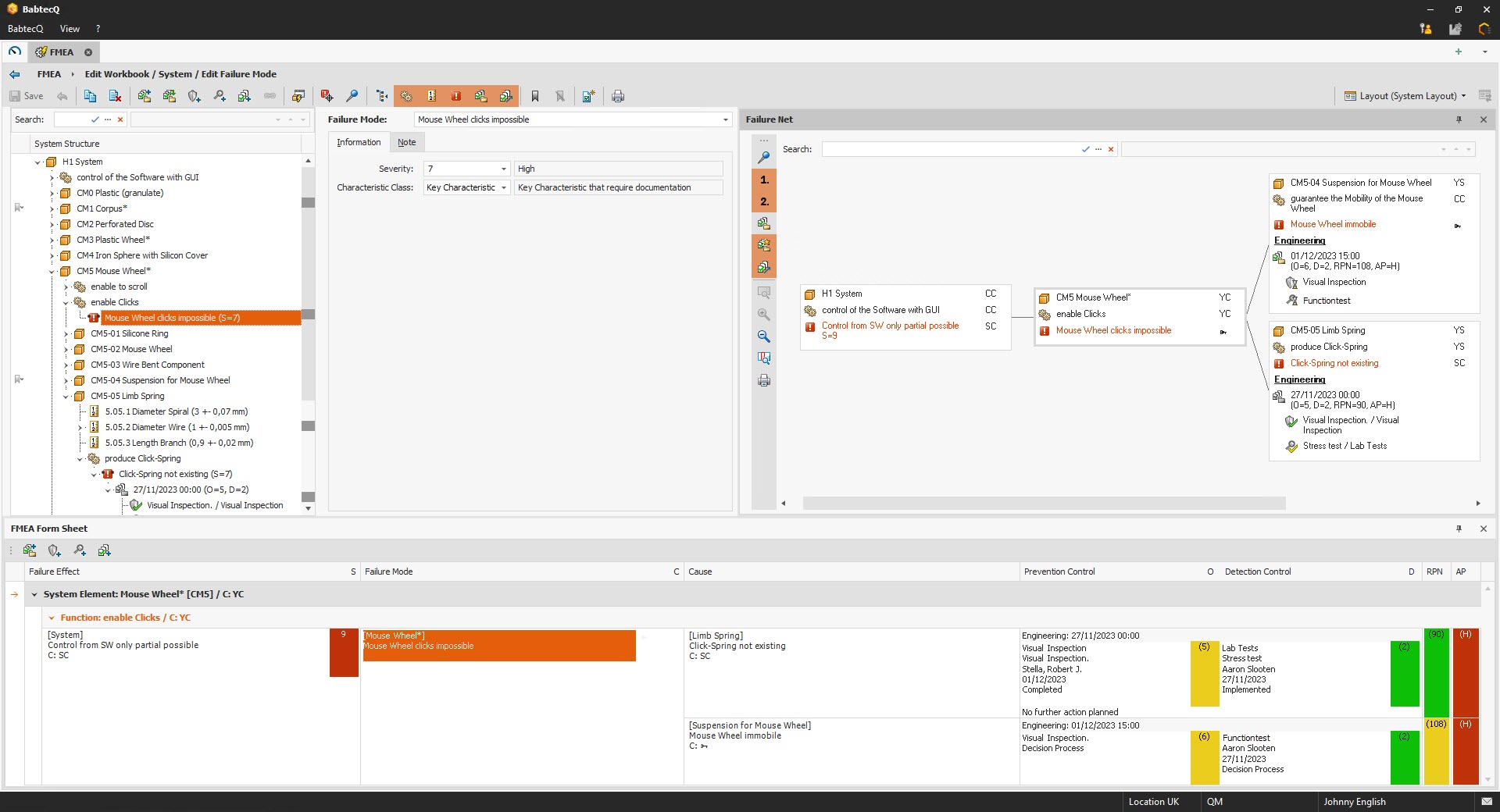

Access clearly-arranged tree structures to perform complex structure, function and failure analyses in the software for FMEA. During the structure analysis, you describe the system to be covered for your product and/or the corresponding process. All required functions and product or process characteristics can be documented – for every system element and every process step. Define dependencies between the required functions in the function tree simply and intuitively via drag & drop. This is how you describe the planned functionality of your product. You can also identify and document possible failure modes with the help of our FMEA program. Failure cause, failure and failure effect can be identified based on cause-effect relationships in the failure net.

Improve your efficiency and create base FMEAs to reference recurring partial systems and processes. For example, if you want to assess processes that are relevant to the manufacturing of various products, but are not defined by product-specific properties, you can manage and assess them in a single base FMEA. In this case, you merely reference the applicable base FMEA in any respective product-specific FMEA. All specific elements as well as those referenced are supplied to the full extent within the software solution for FMEA. Your benefit: You document assessments and process optimizations only in the base FMEA.

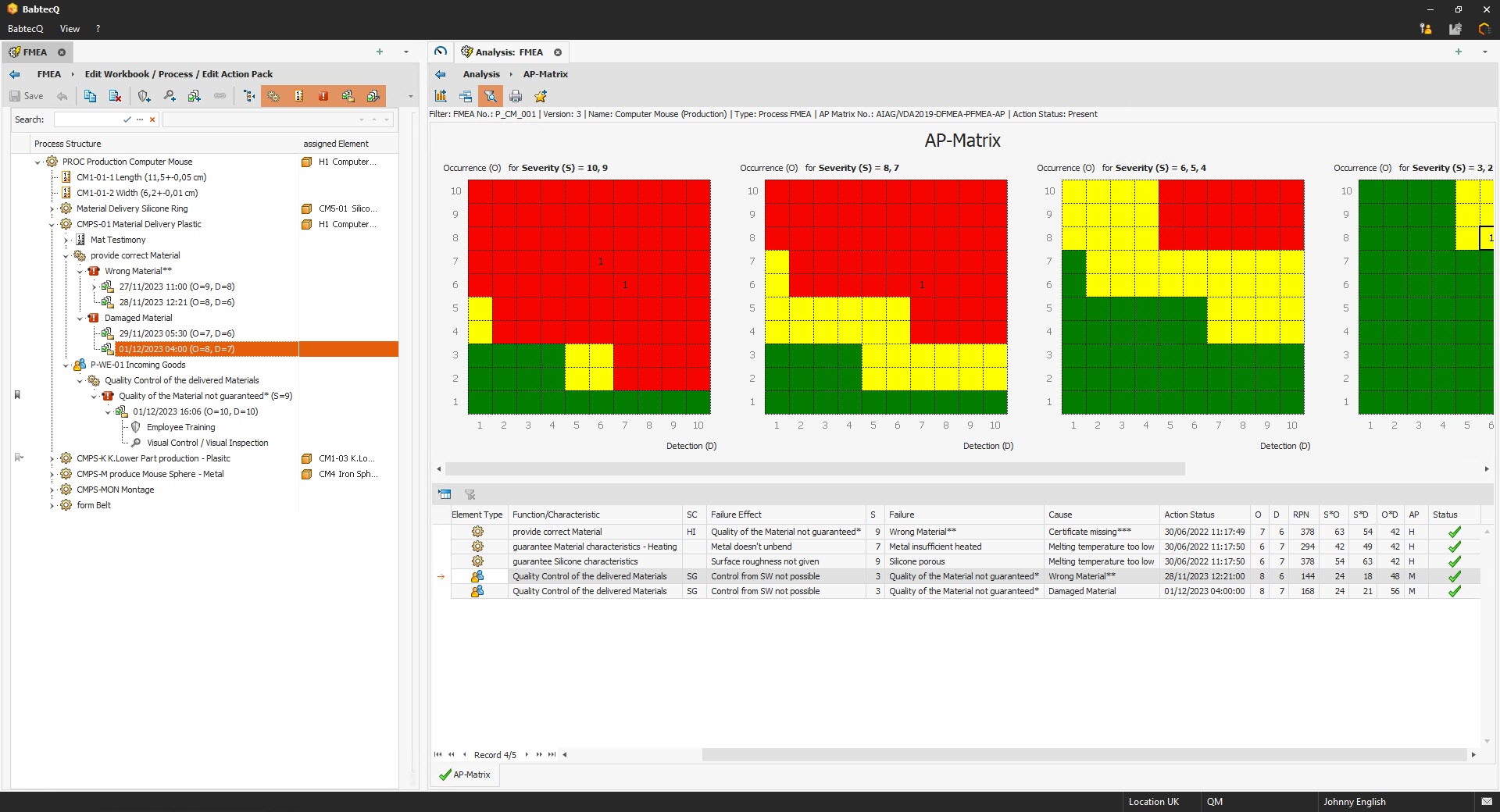

The structure, function and failure analysis is followed by the analysis and assessment of identified risks. Define separate warning thresholds for severity (S), occurrence (O) and detection probability (D). If these warning thresholds are exceeded, the integrated warning system takes action and the determined risk focal points are identified directly in the software for FMEA. After all possible risks have been identified, the automatically determined risk priority number (RPN) or action priority (AP) helps you to find out where there is an urgent need for actions to reduce risk.

You can use our software solution for FMEA during your team sessions as the perfect communication tool: In moderation mode, failure net and form view provide an overview. They form the basis for goal-oriented coordination in the team, e.g., during the creation of prevention and detection actions for identified failure causes. On top of that, create meaningful reports with the help of the FMEA software and convince your customers. With the dynamic report designer, supplied reports and forms can be flexibly adapted to company-specific requirements.

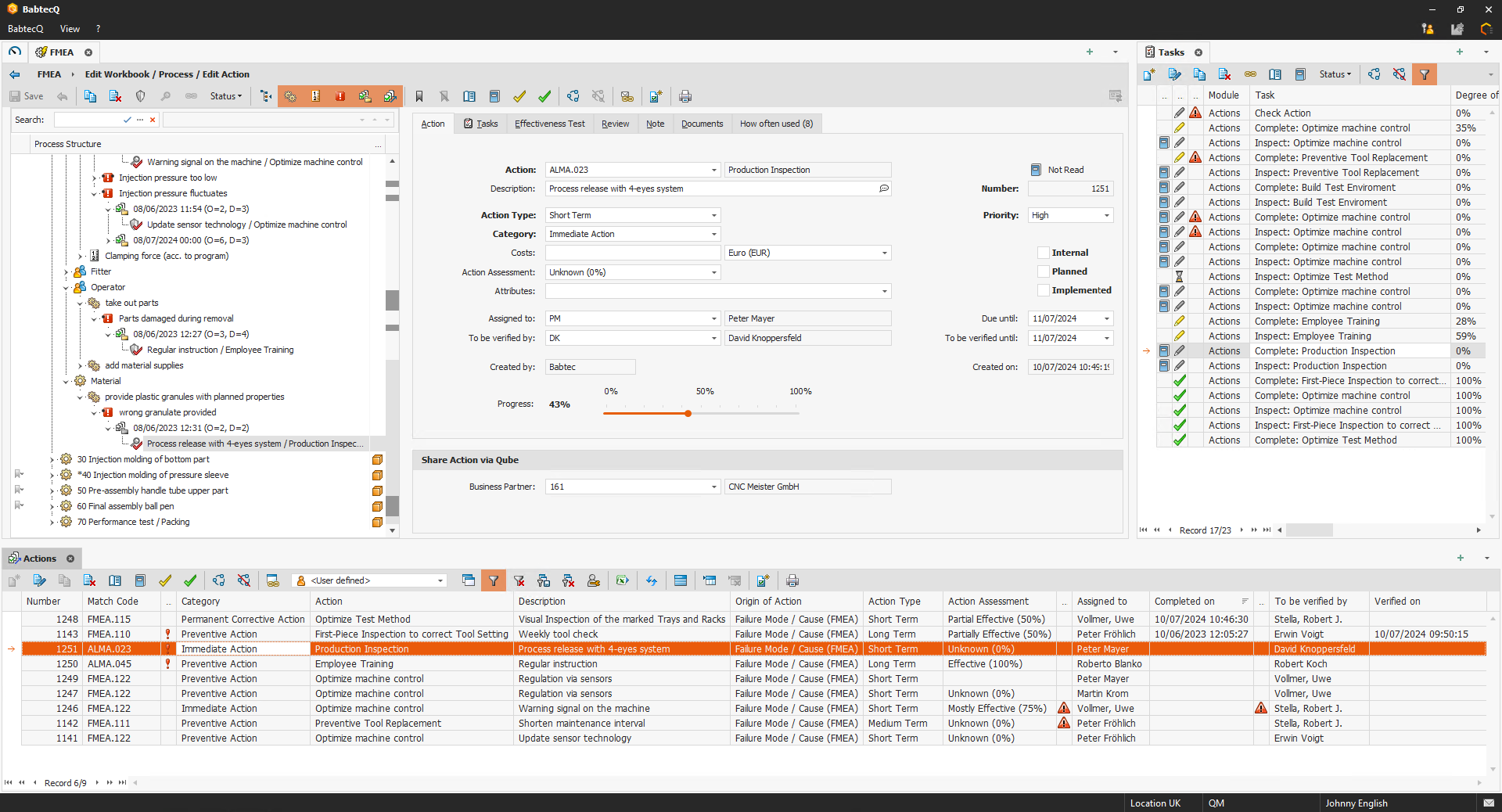

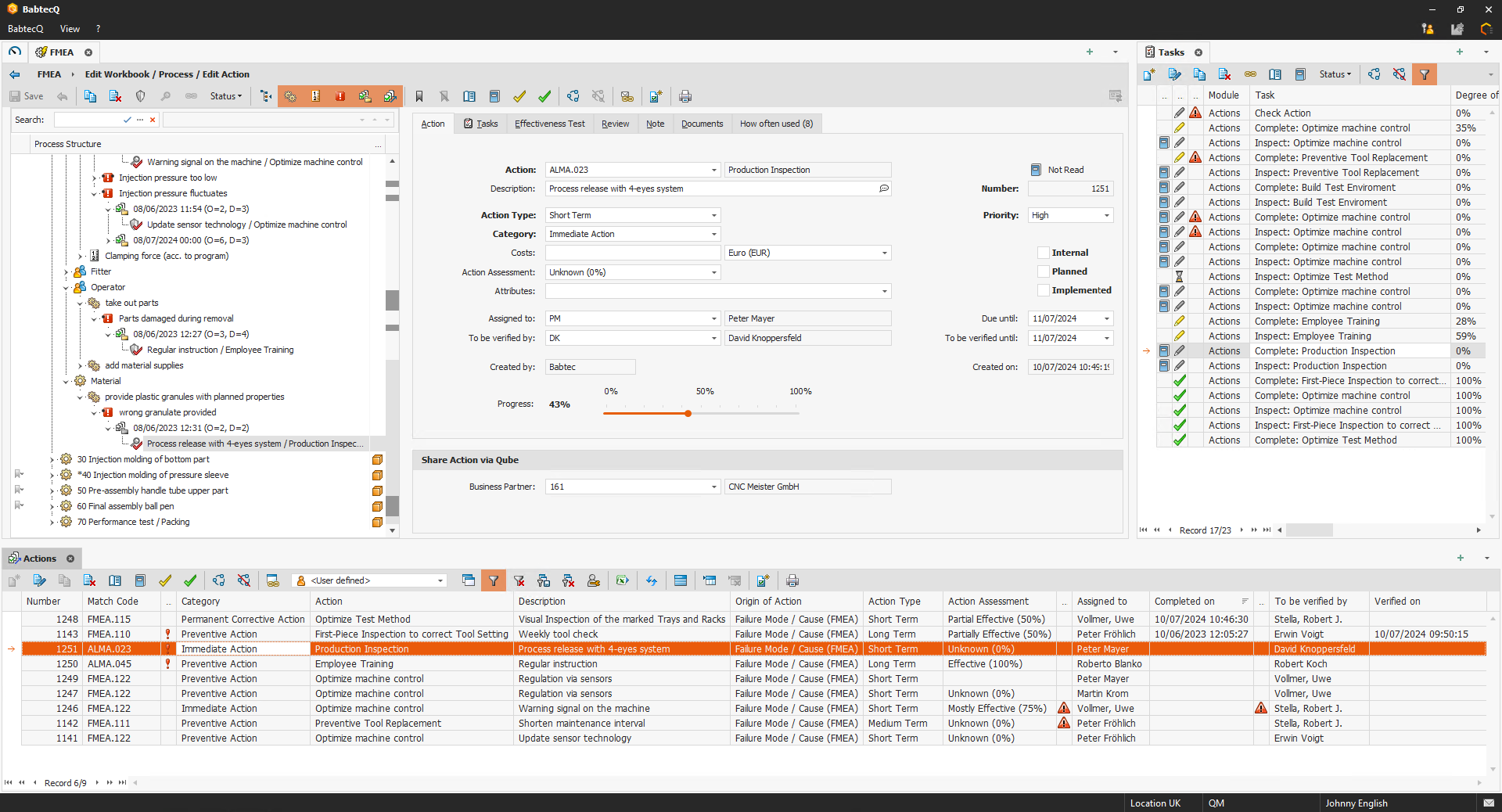

With the risk analysis, you assess the risks initially based on the current prevention and detection actions with the help of the software for FMEA. During the optimization phase, you can reduce existing risks through additional actions and continually perform reassessments. For every developed action, you decide in the team whether it can actually be implemented or has to be discarded. All actions to be implemented are finally adopted in the central action management for processing and tracking.

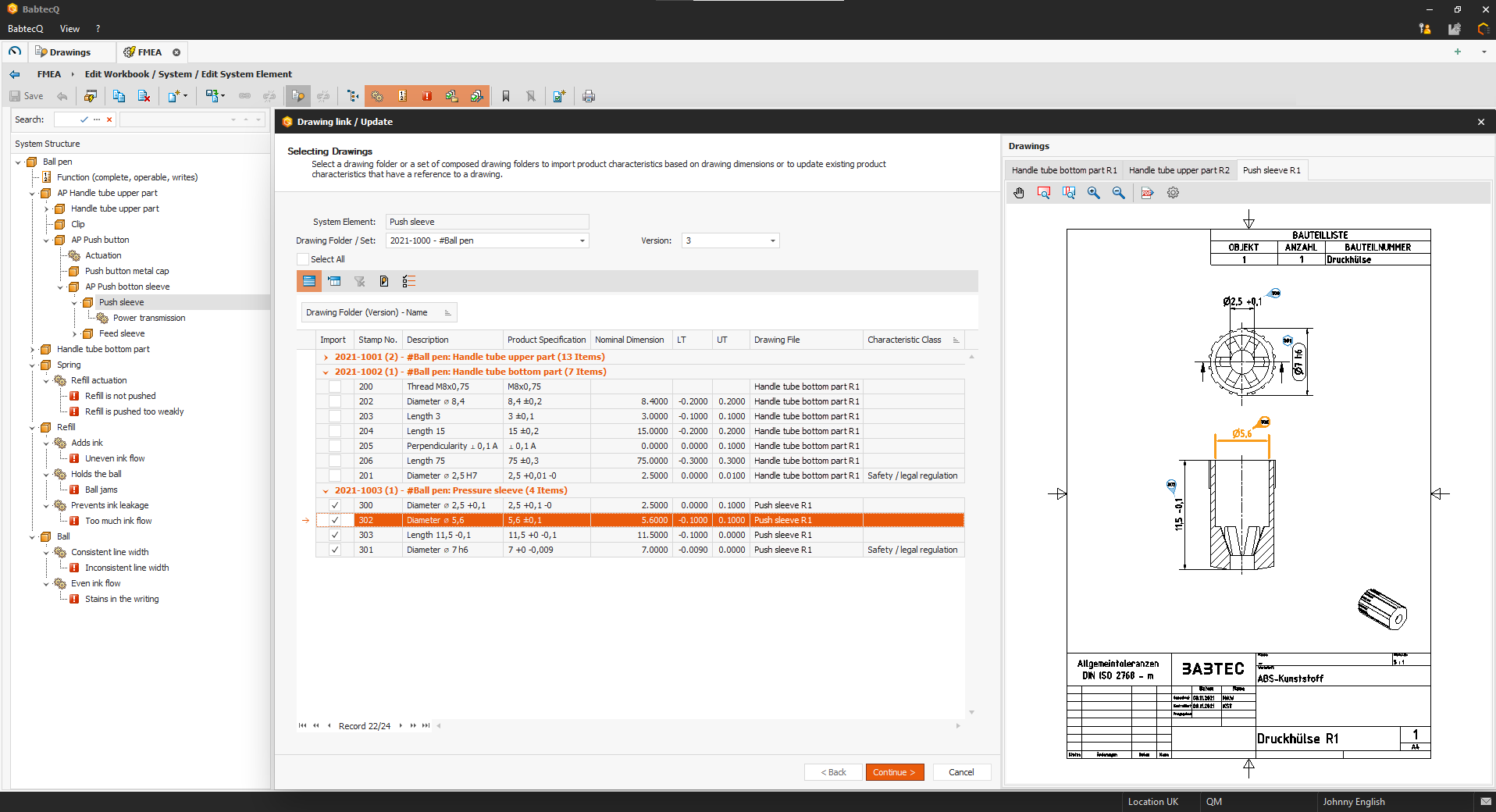

Specifications can be automatically derived from CAD drawings and can be used as characteristics in the FMEA software. Moreover, as an active QM software, BabtecQ automatically and regularly informs you about events that are relevant to FMEAs. For example, you will be informed about all incoming complaints or initiated actions that are essential for the risk analysis or the planning of relevant inspection steps. Use the information potential of customer complaints and adopt the experiences and actions directly into your FMEA. With the linking of FMEAs, control plans and even inspection plans, the integrated change management provides you with convenient support for required changes to these documents – without elaborate and failure-prone data comparison.

Then take the opportunity and secure a non-binding presentation appointment! We would be happy to present the "FMEA" module and its functions to you in more detail!

Companies from a wide range of industries rely on software solutions from Babtec – from medium-sized family businesses to international corporations. Read the success stories of selected customers in our case studies.

Are you interested in finding out more about our software solutions?

Then please use our contact form or get in touch with us by phone!