Of course, you can also reach us via e-mail or our contact form. We will get in touch with you as soon as possible.

All over the world, automotive manufacturers install supplier parts in a wide variety of vehicle models. Those who collect, standardize and analyze field data as part of their warranty management know the failure behavior of their own products – and can initiate suitable corrective measures at an early stage to reduce warranty costs. Read here what Warranty Management is all about:

Warranty management deals with the handling of defective production parts whose faults are only discovered in the field, i.e., at the customer's premises. The aim is to use feedback from the field to identify the causes of defects, initiate corrective actions and increase product quality in the long term.

As part of efficient quality management, warranty management helps to reduce costs and avoid risks by defining a professional process for responding to recourse claims or recalls. Warranty management is used, for example, in the automotive or aerospace industries.

To run a successful warranty management, you need valid data. However, days and weeks often pass before the data that suppliers receive from their customers in the form of debit notes is ready for analysis. Time that the supplier does not have: reviewing the claims received is a necessity that must be done in a very timely manner. The big challenge is therefore to prepare the individual customer data as quickly as possible so that important insights can be derived from it. Risks can be quantified in this way.

Successful warranty management provides you with a well-structured database. This not only serves you to analyze field data, but also enables the traceability of specific cases in the event of returns or recalls. Thanks to the established processes of warranty management, you shine with short response times to recourse claims and increased product quality in the long term.

But to take advantage of these benefits, you first need to collect, standardize and analyze field data. What takes a lot of processing time with conventional solutions, warranty management software usually does automatically. The resources gained in this way can then be used again for the really important tasks: the complex analysis of causes and the initiation of effective corrective measures for the ongoing improvement of products.

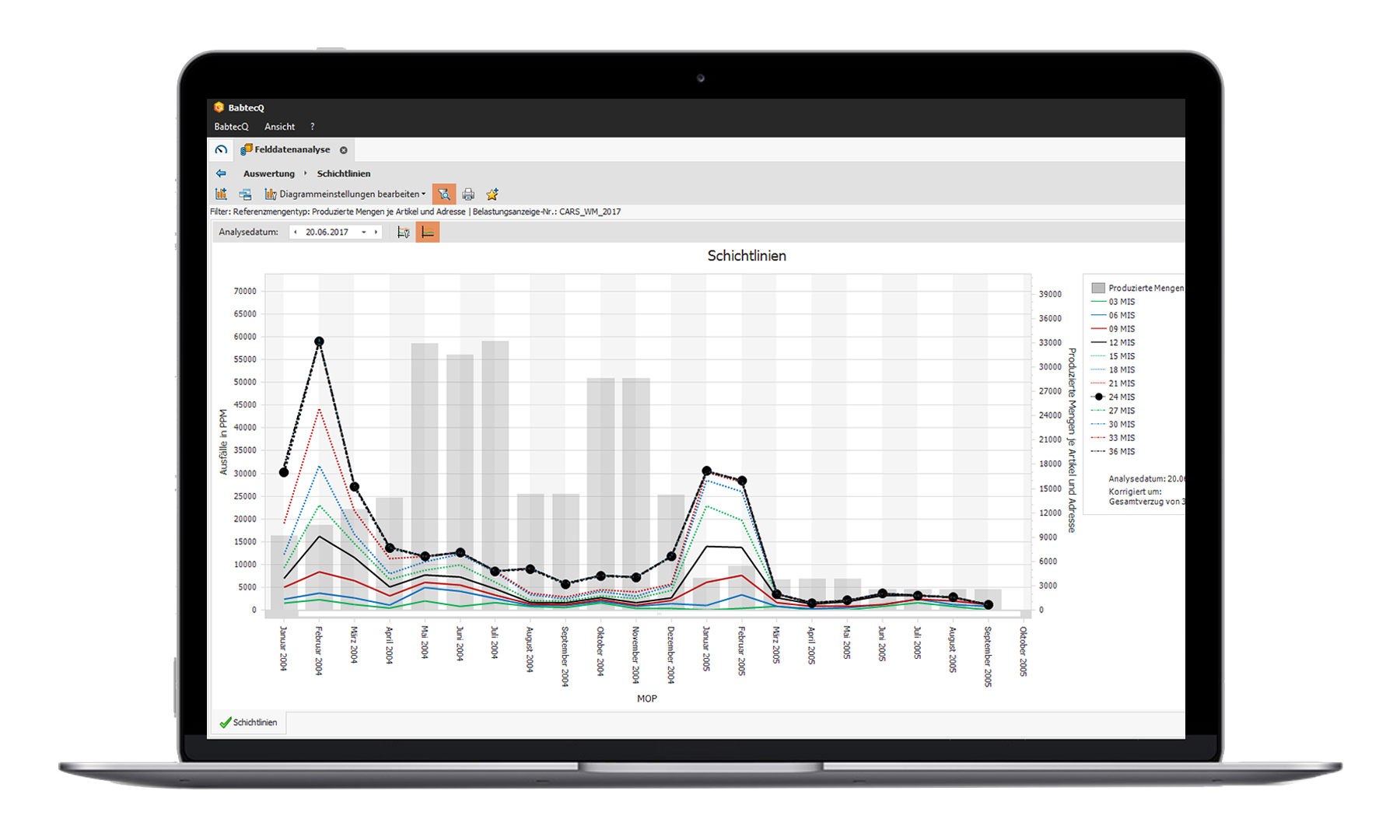

For collecting, standardizing, and analyzing field data, it is advisable to use QM software such as BabtecQ, which also provides the basis for initiating a qualified appeal in case of doubt. The "Warranty Management" software module systematically processes field data and provides valuable information about products in field use.

Anyone involved in quality management and QM systems has probably already come across the term skip lot procedure. This article explains what this sampling procedure is all about and why it can be useful. The term skip-lot (skip a lot) actually brings us pretty close to the general idea: Because this... continue reading

Not everything you need to manufacture your own product you actually produce yourself. Instead, products from suppliers are used. The challenge here is that your own quality depends to a large extent on the quality of the supplier products and the reliability of the suppliers. So, which is the best?... continue reading

Knowing and systematically expanding the qualifications of one’s own employees is not only necessary, but also very sensible. This is the only way to ensure sustainable quality in the company and the satisfaction of the workforce. A helpful tool for this is the qualification matrix. You can read here... continue reading

No Comments