Of course, you can also reach us via e-mail or our contact form. We will get in touch with you as soon as possible.

To manufacture high-quality products, it is essential to plan, manage and track projects in the areas of product development and production in a target-oriented manner. Gaps in the documentation or undetectable documents make planning products of high quality difficult, especially since most product defects originate in the development and planning phase. As part of your advanced quality planning, the software for APQP (Advanced Product Quality Planning) helps you to avoid errors and deviations at an early stage and to counteract time-consuming corrections. In this way, you can ensure at all times that the products meet your customers' requirements.

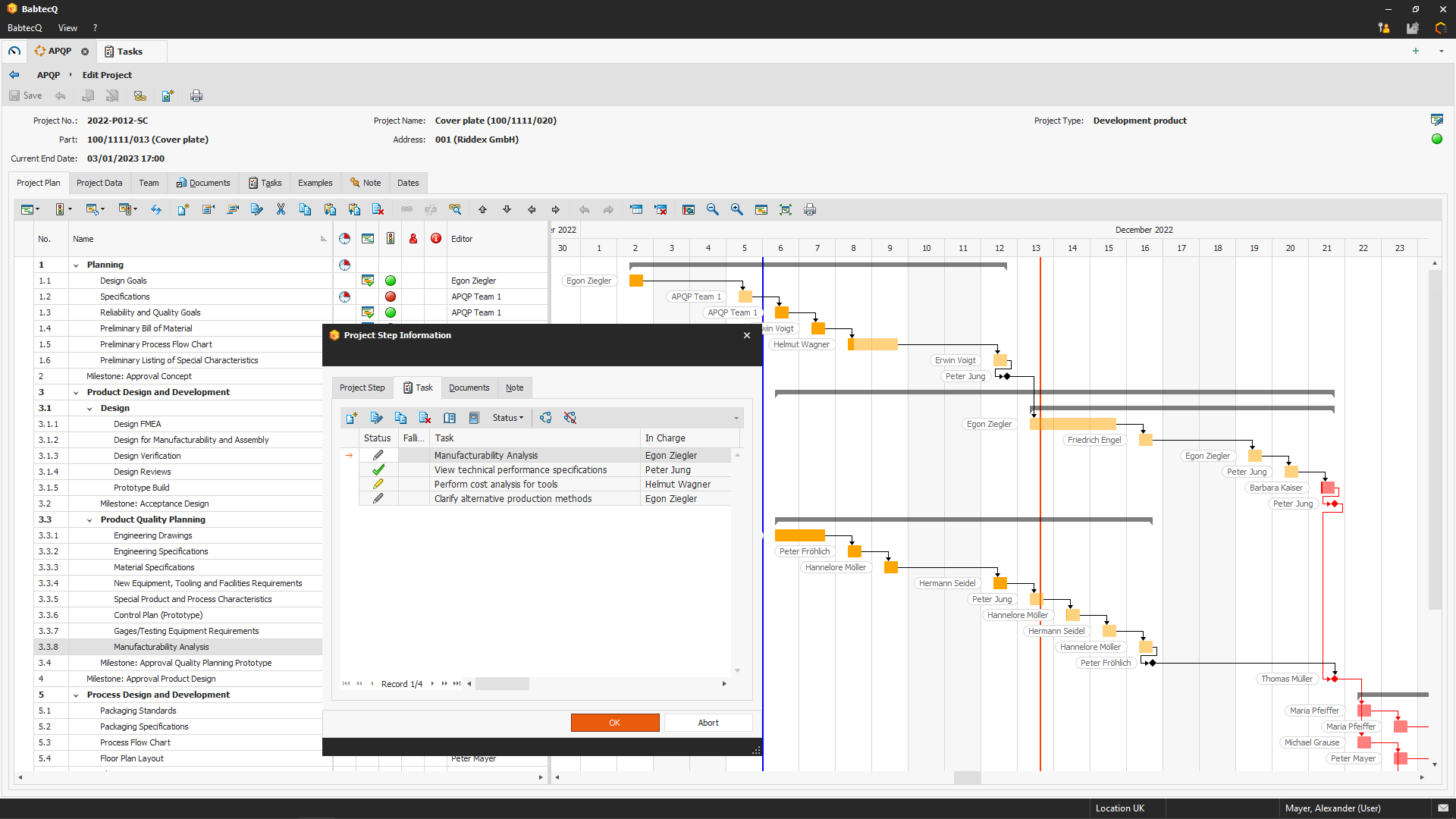

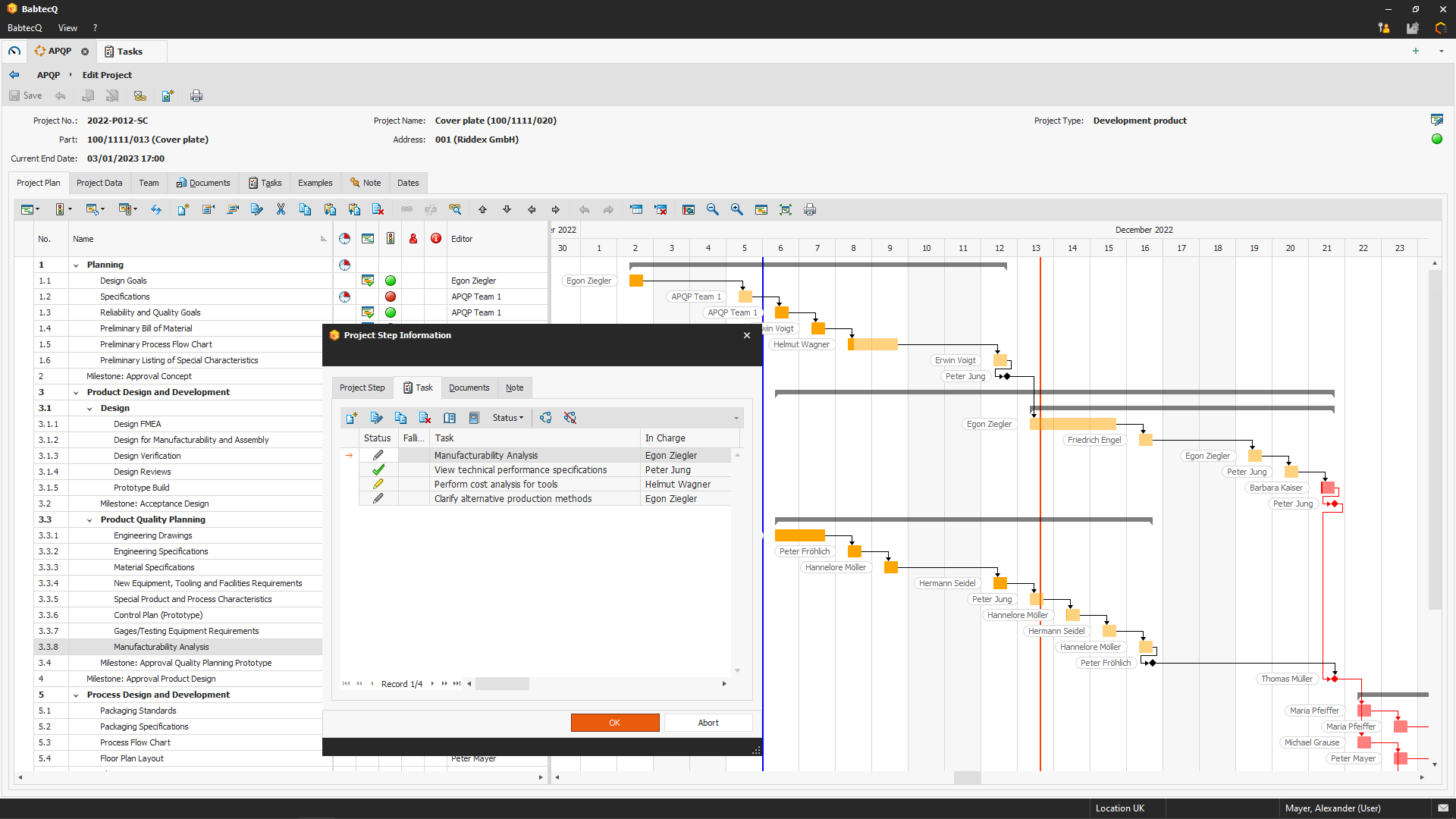

The APQP module of the fully integrated Babtec software allows you to create comprehensive project plans with all the necessary project steps, tasks and agreed milestones. In this way, you plan, manage and track all phases of product development from the idea to series production. The software for APQP thus offers you valuable support in advanced quality planning by helping you to keep track of all internally planned measures and milestones as well as those agreed with suppliers and the customer at all times.

The data and documents relevant to a development project, e.g. from a created FMEA or an initial sampling carried out, can be easily transferred to the APQP project through the integration of the Babtec modules. This data is managed in the APQP software centrally and always in relation to the specific project status. In this way, you fulfill the complete documentation of all quality-assuring measures required by customers. Failures and deviations are thus detected and prevented long before series production.

With its numerous graphical functions, the APQP software effectively supports you in creating and visualizing project plans. The linchpin of advanced quality planning with APQP is the Gantt chart. It clearly displays all project steps including their durations – regardless of whether they run simultaneously or consecutively.

Using intuitive drag & drop, you can move the individual project steps forward or backward as required, plan their processing times and define important milestones within the project. You can visualize dependencies between the individual steps in no time at all and thus determine the structural flow of your project.

Use the opportunities of structured project tracking to meet the milestones agreed with your customers. With the integrated project calendar, you can easily take factors such as working hours or public holidays into account when planning your projects. The comparison of planned and actual data makes it possible to identify and limit delays.

The print function of the software for APQP can be configured individually according to your needs in order to be able to provide well-founded feedback on the project status at team meetings, customer meetings or other occasions. Application-oriented zoom functions allow you as a project manager to transparently monitor both the overall project and individual project steps.

You can also use project templates to organize recurring projects, minimizing administrative work and increasing the efficiency of your project management.

In order to maintain an overview of complex projects, the APQP software allows you to transfer individual task sequences into self-sufficient sub-projects. You then assign these to the responsible persons. The sub-projects remain as steps of the original project, so that deadline monitoring continues to be carried out conveniently in the context of the overall project.

In addition, you have the option of grouping the individual project steps and thus creating subtasks that can be clearly displayed in the Gantt chart and shown or hidden as required.

If deadlines are exceeded, the integrated warning system informs you reliably and immediately in the affected project step. In this way, you can initiate suitable countermeasures. Additionally, you receive status feedback and risk assessments regarding the processing status of your project at any time.

The software for APQP is part of the fully integrated Babtec standard software: You can assign due dates and persons responsible to each project step. The central task management of the Babtec software then enables your team members and you as the project manager to stay informed at all times about the processing status and progress of the individual project steps. This ensures a seamless flow of information between all those involved.

With the help of the browser-based BabtecQ Go interface, your entire team can access the tasks company-wide – even on a smartphone or tablet. In conjunction with the cloud-based QM software BabtecQube, you can even integrate business partners outside your own company into your planning.

You can document the results and quality assurance measures developed within the scope of a project without gaps and in direct connection with the corresponding project step. For your efficient advanced quality planning with APQP, you can store any number of documents, e.g., Word, Excel or PDF files, in the database or link to it.

Thanks to the seamless integration of the various modules within the Babtec software, you can link directly to information and documents from other modules in the APQP software if desired. This allows you view and edit the data from the applicable FMEA, inspection plans, gage capability tests, etc.

The unambiguous versioning of the documents also helps to trace different processing steps without gaps and to prove them internally or to your customers.

Then take the opportunity and secure a non-binding presentation appointment! We would be happy to present the "APQP" module and its functions to you in more detail!

Companies from a wide range of industries rely on software solutions from Babtec – from medium-sized family businesses to international corporations. Read the success stories of selected customers in our case studies.

FMEA: Failure Mode and Effects Analysis

Identify and avoid potential errors during the development process.

FMEA: Failure Mode and Effects Analysis

Identify and avoid potential errors during the development process.

Part Approval Process / PPAP / PPA

Carry out initial sampling on the basis of defined inspection characteristics.

Part Approval Process / PPAP / PPA

Carry out initial sampling on the basis of defined inspection characteristics.

Control Plans

Detailed planning and documentation of production processes.

Control Plans

Detailed planning and documentation of production processes.