Of course, you can also reach us via e-mail or our contact form. We will get in touch with you as soon as possible.

Defects are always possible and can occur even with mature products and processes. If complaints arise due to production errors, companies rely on what is known as complaints management. Read here what it is all about and why it is crucial for quality improvement:

The term complaints management describes the planning, implementation and monitoring of all the steps a company takes when someone complains about something. In this context, complaints management focuses on products in which defects have occurred in the course of industrial series production.

The overriding goal of complaints management is to bring about improvements by finding the cause of the defect. First, the cause of the defect must be determined: What happened in the first place? How could the error have occurred? Once this is known, consequences can be derived: what must be done to avoid the error in the future and prevent damage?

This process also leads to reducing the impact of customer dissatisfaction and restoring customer satisfaction. A working tool often used in modern industry for complaints management is the 8D report, which maps both the search for the cause of the error and the question of its consequences.

Complaints management often refers not only to defective products, but also to complaints in the service industry. In addition to the term complaints management, it is therefore often also called feedback management. Complaints management can refer to all measures that a company takes in connection with customer complaints. In a company, complaints management is therefore part of customer relationship management, or CRM for short.

Depending on the industry, context and business field, a wide variety of types of complaints can occur. Three widely used types are as follows:

A complaint can be seen as an opportunity to improve the quality of a company's own products or processes on the basis of the errors that have occurred. By identifying the causes of errors and exploring ways to prevent them, complaints can be of decisive benefit for quality improvement and the reduction of repeat errors.

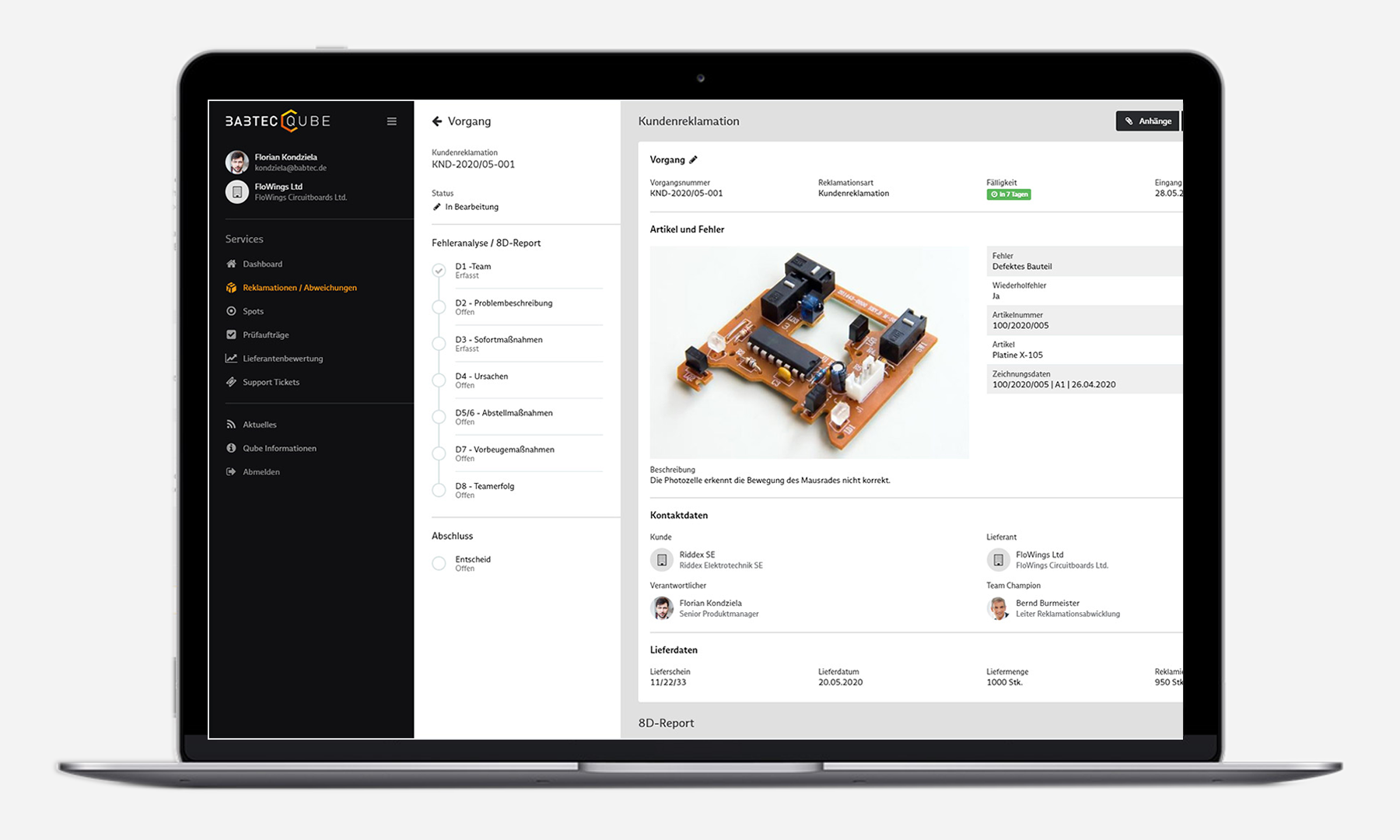

With the support of the right software, complaints management can be implemented efficiently. With BabtecQ QM software, you can process your complaints reliably in configurable workflows. Thanks to the classifications in error catalogs, you can also conduct a targeted root cause analysis.

Modern companies should therefore measure customer satisfaction because the results lead to long-term business success. Read here what constitutes a successful customer satisfaction analysis and why negative evaluations in particular bring so much benefit. ... continue reading

Even if a described management system is required, for example, by customers, standards or laws, its implementation in one's own company can only function well and profitably if all parties concerned understand what obligations are associated with the operation of a management system and what benefits... continue reading

Once we have invested money in a product, we expect it to fulfill its purpose and that we can rely on it. What is an expectation on the part of the customer means work on the part of the manufacturer: in order to meet customer expectations, quality must be assured. To this end, certain processes are... continue reading

No Comments