Of course, you can also reach us via e-mail or our contact form. We will get in touch with you as soon as possible.

Computer-aided design applications (CAD for short) are standard in many manufacturing companies. CAD software helps design products and simulate their behavior in a wide variety of application situations. With our software solution, you automatically stamp the drawing dimensions and use the resulting data in a time-efficient and -effective way to improve the quality of the products.

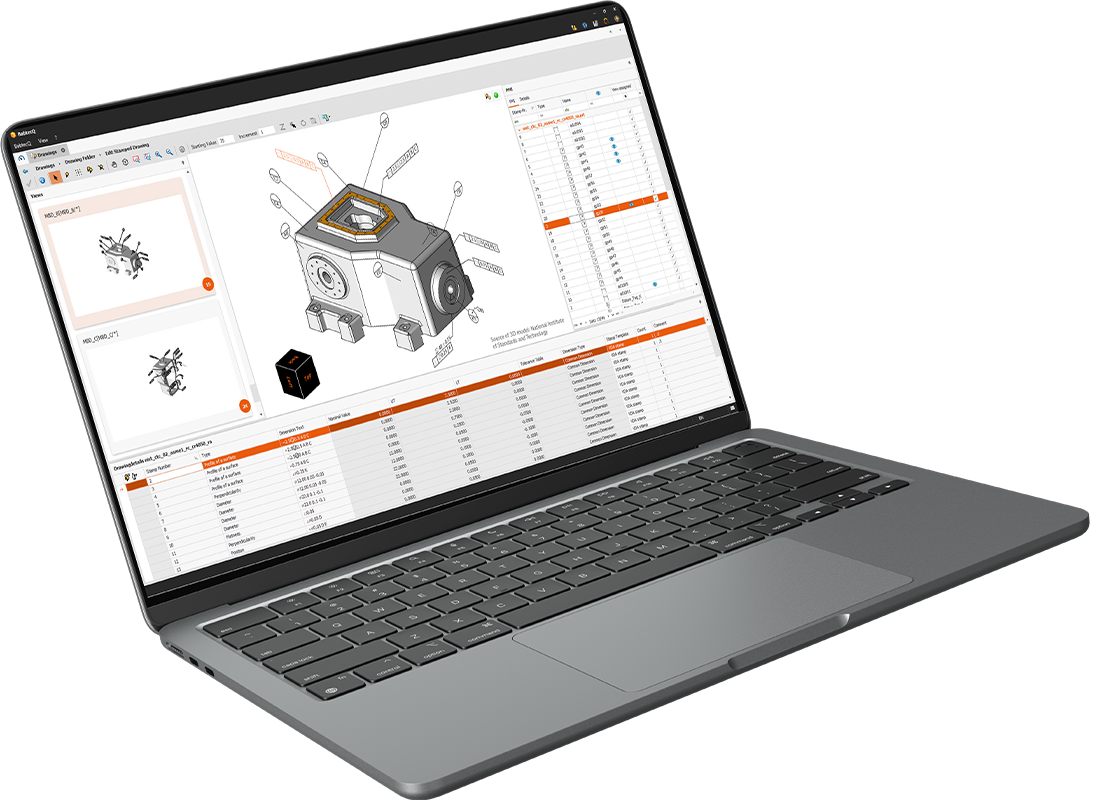

The latest generation of our software will make working with CAD models even more efficient and reliable: With the release of Babtec 8, it will also be possible to process 3D CAD models from December 2024.

This means that in future you will no longer have to derive 2D drawings from your existing 3D models in order to use them, for example, for your quality inspections. Instead, you can load the 3D file from your CAD solution directly into the Babtec software. You can then align, zoom and rotate the three-dimensional model on your screen as you wish and thus identify all the required dimensions. This gives you an even better overview of your product.

A significant advantage of our improved CAD integration in Babtec 8: If a 3D file contains further product specifications in the form of Product Manufacturing Information (PMI), our software recognizes and processes these directly "behind the scenes" during import. This makes the 3D model the central point for all necessary information, the so-called single point of truth. The effort required for data maintenance is therefore also reduced.

If the 3D model does not contain PMI, you can still use a 2D drawing. In this case, you can easily manage 3D model and 2D drawing within a shared drawing folder. As usual, you benefit from the automatic stamping of drawings and the intuitive operation of our CAD integration. The drawing dimensions obtained can be made available to other modules of the Babtec software, for example as part of an FMEA or part approval processes, without media discontinuity.

By supporting numerous additional file formats of common CAD software, including standard formats such as STEP or PDF, but also manufacturer-specific formats such as those from Siemens, Dassault Systems and PTC, the upcoming version of our CAD integration will fit even better into your business processes.

Would you like to find out more about the highlights of our latest software generation?

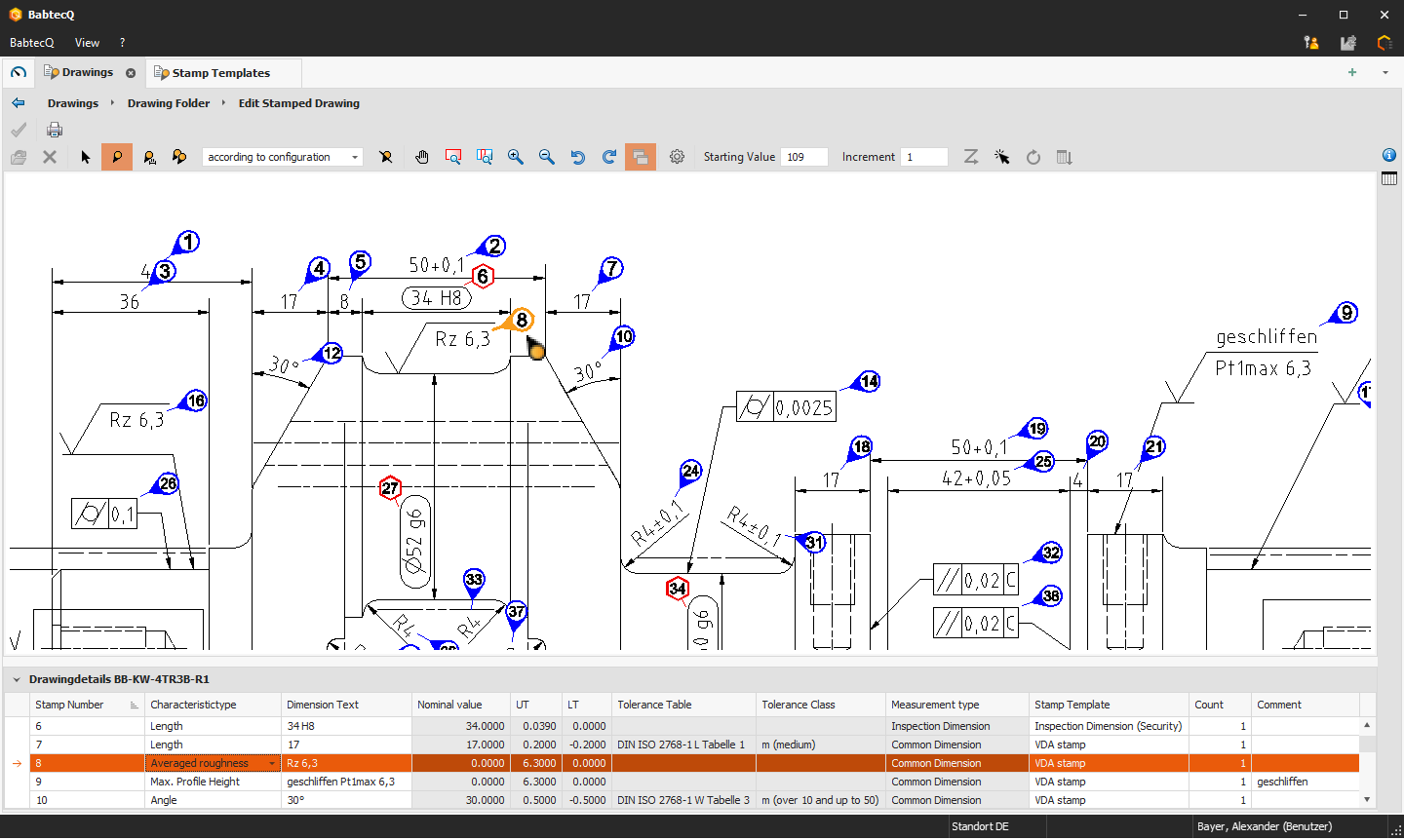

Drawing information are an essential component of quality inspections: with our CAD integration, you can convert product characteristics and dimensions from CAD drawings into quality-relevant inspection data for inspection planning at the push of a button. If the drawings are available in a standardized CAD exchange format (2D DXF, DWG format), inspection characteristics with their characteristic name, drawing dimension and the upper as well as the lower nominal limits can be generated directly from the drawing data. Our automatic detection of drawing dimension also analyzes any text information contained in a PDF file that you could also mark up using a PDF reader. In this way, dimension texts are reliably recognized and prepared as processable drawing dimensions – and without additional OCR software.

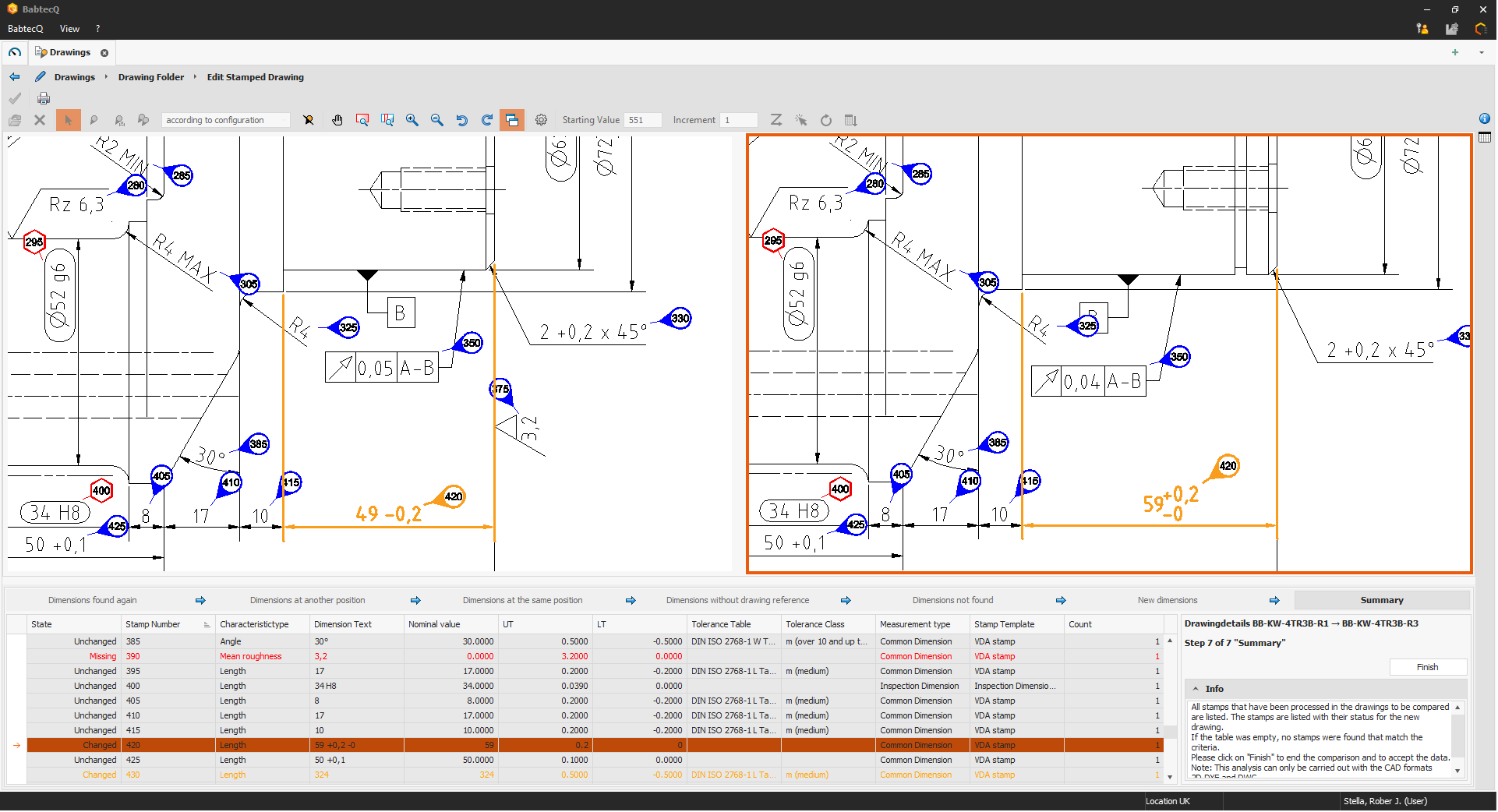

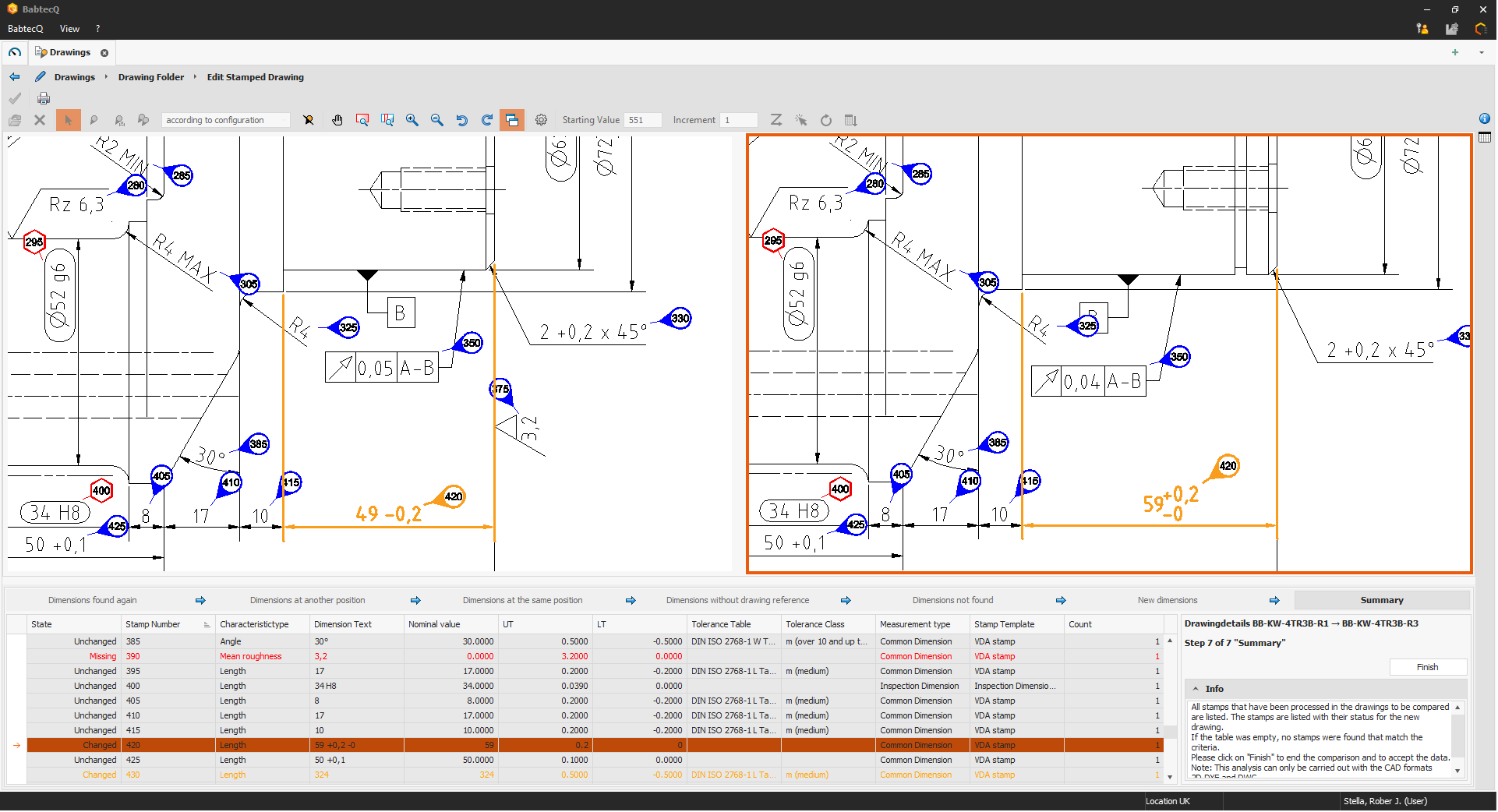

The function “Drawing Dimension Comparison” provides an assistant that enables the comparison of different drawing statuses. It guides you through 7 steps in which you can edit unchanged, moved, changed, omitted and added dimensions. In each step information is available, which explains what happens in this step and how the available tools work. Since the assistant supports you in all steps of the comparison, you get an optimal comparison result with just a few clicks.

For more information, have a look at the CAD integration product sheet in the download area.

Are you interested in finding out more about our software solutions?

Then please use our contact form or get in touch with us by phone!

CAD (Computer Aided Design) refers to the design of products using computer-aided graphics creation.

Like CAQ (Computer Aided Quality), CAD is also part of the CAx technologies, which encompass production-related applied computer science in production. From geometric modelling and simulation over transfer to manufacturing, CAD supports a wide range of activities in the design process.

CAD can be used to create documents for the manufacture of a product - for example assembly plans or technical drawings. In concrete terms, CAD comprises the following three phases: The conception in which requirements are made; the design in which solutions are concretized and the detailing in which parts lists, individual parts and production documents are added. The main advantages of CAD are the great cost and time savings that are achieved by automating the design process and the possibility to modify designs more quickly and less cumbersomely.

CAD systems are used for two-dimensional technical paper drawings; in mechanical engineering, on the other hand, 3D geometry systems are common today, with which the edge, surface and volume models can be represented three-dimensionally.